Need Pre-baked Anode Carbon Block? Please Contact Us!

Pre-baked Anode Carbon Block for Aluminium Electrolysis Smeltering

OVERVIEW

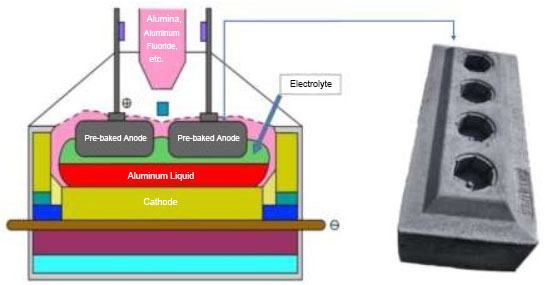

Anode carbon materials include carbon anode block, anode paste. The anode carbon materials are widely used in electrolytic aluminum industry. Pre-baked anode carbon blocks are the main auxiliary material for producing aluminum ingot from alumina.

Anode carbon block, known as pre-baked anode carbon block, is also known as carbon anode for aluminum electrolysis.

WHAT WE OFFER

TechSolutions offer pre-baked carbon anode block to aluminum manufacturers or trading company worldwide.

We supplied pre-baked anode carbon block features low content of ash and sulfur, good formability and high strength. Our supplied pre-baked anode carbon block products enjoy great reputation in China and international markets, winning plenty of favorable feedbacks from customers.

TechSolutions offered pre-baked anode carbon block is produced in conformity with the China national nonferrous industry standard YS/T 285, China standards GB, ISO standard or client customized standards.

TechSolutions also provide prebaked anode carbon block plant integrated solutions from engineering design, equipment supply, construction to operation and maintenance services. In addition, we offer raw materials and auxiliary materials needed for producing pre-baked anode carbon block, such as calcined petroleum coke (CPC), green petroleum coke, etc.

KEY BENEFITS

TechSolutions offer key benefits to clients when we supply pre-baked anode carbon blocks:

- Advanced technology and ensured quality: Our pre-baked anode manufacturing base is demonstration enterprise and green plant in the pre-baked anode industry. We have been providing excellent pre-baked anode products for China and international market aluminum smelting enterprises for more than 10 years, which can meet the quality requirements of various customers for pre-baked anodes.

- Competitive price: We realize the large-scale procurement of raw materials through global procurement, coupled with continuous improvement of technical process, to reduce the production cost and price of pre-baked anode.

- Guaranteed delivery date: We have 3 manufacturing bases in China, the production capacity reaches 1.05 million tons, with sufficient guaranteed delivery date.

PRODUCT FEATURES

Functionality

The production technology of our pre-baked anode carbon blocks is advanced and using first-class equipment. We can supply high-quality pre-baked anode carbon blocks with low sulfur, low iron and excellent physical and chemical indicators, which provides support to production of energy-saving, environmentally friendly and low-carbon aluminum.

Our company’s pre-baked anode carbon blocks are made of high-quality petroleum coke and electrode asphalt, and are produced by pot-type calcination process without additional fuel, as well as advanced processes such as medium and fine grinding, kneading, molding and roasting. The pre-baked anode carbon blocks have the characteristics of low ash content, low sulfur content, good plasticity and high strength.

Typical features are below:

- CO2 reactivity residue can reach above 91%, air reactivity can reach above 96%; The life-span in aluminum electrolysis smelting cells is 30-33 days, with our pre-baked anodes the carbon consumption required for producing 1 ton primary aluminum will reduce by about 30kg than using pre-baked carbon anodes produced by others.

- Higher Thermal Shock Resistance

Thermal Exposure: <4 ×10

Heat Conductive: <3W/mkl 3.Higher Current Density Current density: > 0.8A/cm2 - Lower Electrical Resistivity

Electrical Resistivity: 55-56μΩm

Our Pre-baked Anode Range

TechSolutions can provide pre-baked anode carbon blocks required for aluminum smelting production for various types of aluminum reduction cells, including but not limited to 160kA, 200kA, 240kA, 300kA, 320kA, 350kA, 420kA, 500kA, etc. (200kA, 300kA, 400kA, 500kA).

We also provide anode carbon block as per required technical data from clients.

Customized Design according to Client’s Unique Requirements

TechSolutions can customized supply pre-baked anode carbon blocks that meet the technical specifications according to the production requirements of aluminum smelting enterprises all over the world.

Technical Data

The major physiochemical technical data for pre-baked anode carbon block in China national nonferrous industry standard YS/T 285 for pre-baked carbon anode block is shown as follows:

| Type | Ash ≤ % | Resistivity ≤ μΩ·m | Strength of resistance to crushing ≥ Mpa | Volume density ≥ g/cm3 | True density ≥ g/cm3 |

| TY-1 | 0.5 | 57 | 35 | 1.55 | 2.04 |

| TY-2 | 0.8 | 62 | 32 | 1.52 | 2.02 |

Industrial Standards for Prebaked Carbon Anodes

YS/T 285-2012 Prebaked Anode for Aluminium Electrolysis

ISO 12980:2000 Carbonaceous materials used in the production of aluminium – Green coke and calcined coke for electrodes — Analysis using an X-ray fluorescence method

GB/T 26297.3 Sampling of carbonaceous materials used for aluminium production – Part 3:Prebaked blocks (ISO 8007-2:1999,Carbonaceous materials used in the production of aluminium—Sampling plans and sampling from individual units – Part 2:Prebaked blocks,MOD)

YS/T 63.2 Carbonaceous materials used in the production of aluminium part 2: Cathode blocks and prebaked anodes – Determination of electrical resistivity at ambient temperature

YS/T 63.3

YS/T 63.4

YS/T 63.7

YS/T 63.9

YS/T 63.10

YS/T 63.11

YS/T 63.12

YS/T 63.14

YS/T 63.15

YS/T 63.16

YS/T 63.19

YS/T 587.9

ISO 11713-2000 Carbonaceous materials used in the production of aluminium – Cathode blocks and prebaked anodes – Determination of electrical resistivity at ambient temperature

Baked apparent density ISO 12985-1

Electrical resistance ISO 11713

Compressive strength ISO 18515

Young’s modulus RDC-144

Tensile strength ISO 12986-1

Thermal conductivity ISO 12987

Coefficient of thermal expansion RDC-158

Air permeability ISO 15906

Carboxy reactivity residue ISO 12988-1

Air reactivity residue ISO 12989-1

How can we help you?

Whether you’re looking for information about our pre-baked anode carbon plant plant solution, carbon anode block products, services, or technical documentation, if you need support, just chat with our customer care centre:

Tel: +86 21 6890 6101

E-mail: service@techsolutions.com.cn

Alternatively, you can contact our sales team using contact form.

FAQs

What is pre-baked anode carbon block?

Pre-baked anode is a kind of carbon block produced by proportioning, kneading, forming and roasting with calcined petroleum coke and pitch coke as aggregate and coal pitch as binder. This kind of carbon block is called pre-baked anode carbon block because it has a stable geometric shape after roasting before being used in electrolytic cell, and it is also called carbon anode for aluminum electrolysis customarily. Pre-baked anode is used as the anode material of pre-baked aluminum smelting cell.

Pre-baked anode used in aluminum electrolysis smelting is one of the main materials in aluminum smelting production, which consumes about 500 kilograms of anode carbon block per ton of aluminum smelting production. It is not only the conductive anode of aluminum smelting cell, but also participates in electrochemical reaction, and is called the “heart” of aluminum electrolysis smelting cell. Its quality has great influence on many economic indexes and benefits of aluminum electrolysis smelting production, and it is an irreplaceable consumable material in current aluminum smelting process.

Pre-baked anode carbon block is the 2nd important raw material for aluminum smelting except alumina.

The aluminum electrolysis cell with prebaked anode carbon block as anode is called prebaked anode electrolysis cell, or prebaked cell for short.

The anode block is generally cuboid, and there are 2~4 round grooves with a diameter of 160~180mm and a depth of 80~110mm on its upper surface in the conductive direction, commonly known as the carbon bowl. When the anode is assembled, the carbon bowl is used to place the anode claw head, and the anode guide rod and the anode block are connected into a whole by pouring phosphorus pig iron to form an anode carbon block group. The anode block has different sizes according to the current of the electrolytic cell and the process, but the current density through it is generally 0.68~0.95A/cm2, and the service period is 26~32 days.

Pre-baked carbon anode is easy to operate, easy to realize mechanization and automation, and the anode voltage drop is lower than that of self-baked anode, which eliminates the asphalt smoke in the electrolysis process and is beneficial to the development of electrolytic cell towards large capacity. Therefore, the new-built aluminum smelting plants all adopt pre-baked carbon anode.

Technical Data

Standard

YS/T 285, ISO, GB, etc.

ASH CONTENT

≤0.5% or as required

PRODUCT TYPE

Pre-baked carbon anode block, Anode paste

MARKET

Worldwide