Need circular stockyard stacker relcaimer? Let’s start the conversation

Circular Stockyard Stacker Relcaimer for Bulk Material Handling

Client Benefits

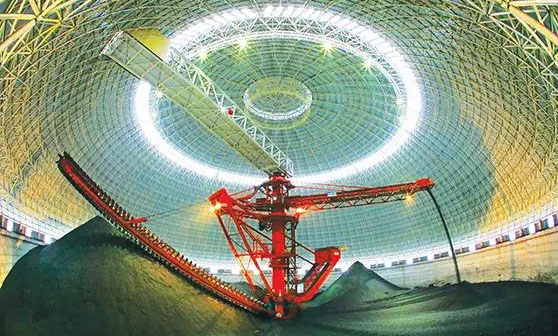

- Fully enclosed, better environmentally friendly performance, improve environment performance of the place of use (power plant, port, mining, metal plant, chemical plant, etc.)

- Small space, save construction land and reduce CAPEX investment.

- Fully automatic operation, minimized manual operation and maintenance costs, improve production efficiency and safety and reliability, reduce OPEX investment.

- Fully free from bad weather.

TechSolutions offer Circular Stockyard Stacker Relcaimer with High-efficiency

Overview

TechSolutions can provide various types of circular stockyard stacker reclaimer according to clients’ actual requirements. The maximum stacking capacity of customized circular stockyard stacker reclaimer can reach 8,500 t/h, and the maximum reclaiming capacity can reach 5,500 t/h or more. The customized circular stockyard stacker reclaimer can be used for the storage, blending & mixing and other operations of coal, ore, ore sand, petroleum coke, sulfur, grain, salt and other different bulk materials.

TechSolutions is capable of design, modularized fabricate, install & commission various different types of circular stockyard stacker relcaimers according to client’s technical requirements, whether the stackers are stationary or luffable stackers, reclaimers are boom type scraper or semi-portal / portal type scraper reclaimers.

Detail capacity and other technical data of circular stockyard stacker relcaimer can be customized by clients, the capacities of TechSolutions circular stockyard stacker relcaimer can be from 300 t/h to 8,500 t/h for reclaiming and 100 t/h to 5,500 t/h, while stockyard diameter can range from 70 to 150 meters.

Similar to all TechSolutions designed bulk material handling equipment, the operation modes of circular stockyard stacker relcaimers can be local control & operation, manual operation, manual remote control, semi-automatic unmanned operation and full-automatic smart unmanned operation.

Types / Product Range

The circular stockyard stacker reclaimer used in circular stockyard system for buffer storage can be divided into four types according to different structures of reclaimer and stacker, namely:

- Stationary boom stacker and boom scraper reclaimer

- Stationary boom stacker and semi-portal scraper reclaimer

- Luffable boom stacker and boom scraper reclaimer

- Luffable stacker and semi-portal scraper reclaimer

Main Features

Main Components of Circular Stockyard Stacker Relcaimer

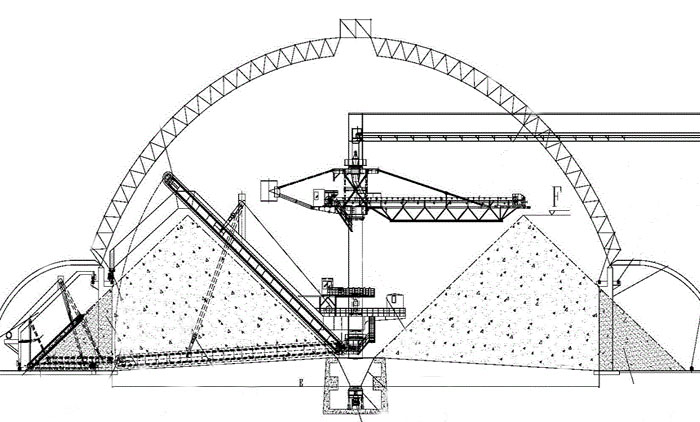

Circular stockyard stacker reclaimer is composed of cantilever stacker, central column, reclaiming slewing luffing mechanism, scraper reclaimer, accessory structure, electrical room and cabin, electrical & control system, etc.

Technical Data

| Specification | Value |

|---|---|

| Stacking Capacity | 300 t/h to 8,500 t/h |

| Typical Belt Width | 650, 800, 1000, 1200, 1400, 1600, 1800, 2000, 2200 mm |

| Typical Belt Speed | 1.00, 1.25, 1.60, 2.00, 2.50, 2.80, 3.15, 3.50, 4.00, 5.00 m/s |

| Reclaiming Capacity | 100 t/h to 5,500 t/h |

| Typical Scraper Blade Dimension (Width) | 1000, 1300, 1500, 1800, 2000, 2200, 2500, 2750, 3000, 3150, 3300 mm |

| Typical Scraper Blade Dimension (Height) | 200, 250, 300, 360, 400, 450, 500, 550, 600, 650, 700 mm |

| Typical Chain Pitch | 250, 315, 400, 500 mm |

| Slewing Angle | 360° or non 360° |

| Bulk Material Density | 0.3 – 3.5 t/m3 |

| Bulk Material Size | 0 – 300 mm |

Our Performance

TechSolutions and its partner have successively provided more than 250 sets of circular stockyard stacker reclaimer in power, steel, petrochemical, coal, metallurgical and other industries, ranking first in market share.

The market share of circular stockyard stacker reclaimer products is as high as over 70%, and the market share of circular stockyards with diameters of over 120 meters is in an Absolute Leading Position.

Key Technical Data Required for Circular Stockyard Stacker Reclaimer Ordering / Quotation

Required Information for Circular Stockyard Stacker Reclaimer Quotation – TechSolutions (PDF)

Please send filled “Required Information for Circular Stockyard Stacker Reclaimer Quotation” form to us by E-mail: service@techsolutions.com.cn

How can we help you?

If you would like to know more about the use of circular stockyard stacker reclaimer in your industry, how they work, or which solution is best for your business, why not get in touch with our dedicated and knowledgeable team at TechSolutions? With nearly 30 years of experience and some of the best engineers in the industry, you can trust us to provide you and your business with the best solutions, no matter what they may be. So, what are you waiting for?

If you need support, just chat with our customer care centre:

Tel: +86 21 6890 6101

E-mail: service@techsolutions.com.cn

Alternatively, you can contact our sales team using contact form.

Interested in the quality services provided by TechSolutions? Check out our brochure and detail performance list Circular stockyard stacker reclaimer for more information.

FAQs

1. What is Circular Stockyard Stacker Relcaimer for Bulk Material Handling?

Circular stockyard stacker reclaimer is a kind of large equipment installed in a closed circular stockyard system, is also a continuous and efficient bulk material handling machine, which can continuously stack, reclaim, blend and mix bulk materials with high efficiency. The circular stacker reclaimer is mainly used for stacking, reclaiming, storaging, blending and mixing bulk materials such as coal, ore, ore sand, limestone, petroleum coke, grain, industrial salt, etc. in ports, steel mills, coal-fired thermal power plants, mines, petrochemicals and other industries.

2. How Circular Stockyard Stacker Relcaimer Works?

Circular stockyard stacker relcaimers are used for bulk material handling applications, which has compact structure, can stack and reclaim bulk material simultaneously. Circular stockyard stacker reclaimer is designed to stack bulk materials transported by trestle belt conveyor system to the circular stockyard or reclaim bulk materials through scraper in the stockyard then put the bulk material into hopper and chute system under the central column.

Bulk materials are transported to the trestle belt conveyor in the circular stockyard via the transfer station, the trestle belt conveyor passes through the dome roof and is supported at the top of the central column of the circular stockyard stacker reclaimer. The transported materials are stacked into a circular cone shaped stockpile by the circular stockyard stacker, and the circular stockyard scraper reclaimer scrapes the bulk materials into the cone hopper and chute sytem under the central column along the slope of the stockpile, then outputs the bulk materials through the vibrating feeder and the underground belt conveyor.

You can read more about the working process in the article “How Does Circular Stockyard Stacker Relcaimer Work?”

3. What Are The Applications of Circular Stockyard Stacker Reclaimer?

The circular stacker reclaimer is mainly used for stacking, reclaiming, storaging, blending and mixing bulk materials such as coal, ore, ore sand, limestone, petroleum coke, grain, industrial salt, etc. in ports, steel mills, coal-fired thermal power plants, mines, petrochemicals and other industries.

Circular stockyard stacker relcaimer is an efficient machine for continuously stacking or reclaiming of bulk materials with particle size less than 300mm in storage yards, which widely used in coal-fired thermal power plants, ports and terminals, steel plants, coking plants, mines, alumina refinery plants, cement, building material, chemical and other industries, can stack or reclaim bulk material such as coal, ore or bauxite continuously.

Technical Data

STOCKYARD DIAMETER

up to 150 meters

STORAGE CAPACITY

up to 300,000 m³

STACKING CAPACITY

up to 8,500 t/h

RECLAIMING CAPACITY

up to 5,500 t/h

Note: Above data can be adapted and may vary according to client’s requirement.