Need Modular Fabrication Solutions? Let’s Start Conversation

Modular Fabrication: An Innovative Solution for Steel Structures and Pipe Modules

Resource developers is always looking for ways to improve efficiency during their facilities construction, reduce costs, short possible time and increase degree of cost-and-schedule certainty. The main challenges for these major projects are Return on investment, speed to market, and capital-intensity-level requirements.

Modular fabrication has emerged as a revolutionary solution to meet these demands. TechSolutions is a leading provider of modular fabrication integrated solutions, specializing in equipment, facilities, steel structure modules and pipe modules for mining, metal, power, oil & gas, chemicals, offshore, etc. Our integrated module execution solutions ensures that every aspect of project implementation is taken care of, from design, project management to procurement, construction, pre-commissioning, and commissioning, to mitigate key risks.

What is Modular Fabrication?

Modular fabrication is an modern construction method or process that involves the constructing prefabricated modules or assemblies in a controlled environment, such as a factory, and then transporting them to the construction site for final assembly. The modules are designed to fit together seamlessly, like pieces of a puzzle, resulting in a faster, more efficient construction process.

Modular fabrication is commonly used in the construction of steel structures and pipe modules, as it allows for a faster and more efficient construction process, which can be used for a wide range of applications, from mining, metal, port to metal, power, oil & gas, chemical plants, etc.

Clients Benefits of Modular Fabrication

Modular fabrication offers numerous benefits to clients projects. Some of these benefits include:

- Cost savings

Modularization can reduce costs in various ways. First, the pre-engineered modules are constructed in a controlled environment, which minimizes the need for expensive on-site construction equipment and on-site labor, and reduces the risk of costly delays due to weather conditions, ensures that there is less waste, fewer errors, and better quality control. Secondly, the use of pre-engineered modules reduces material waste, which translates to lower material costs. According to statistics, modularization can reduce project costs by up to 20% compared to traditional construction methods. - Time savings

Since the modules are off-site prefabricated in a controlled environment, there are no weather delays, and work can continue even in adverse conditions, and on-site construction activities can be performed simultaneously with the off-site construction of modules. The modules are transported to the project site only when they are ready to be installed, reducing on-site construction time. According to statistics, modularization reduces the overall project timeline by up to 50% compared to traditional construction methods. - Improved quality control

Modularization allows for better quality control since the modules are built in a controlled environment. The modules are inspected at every stage of the fabrication process, ensuring that they meet all project requirements, and any issues can be rectified before installation. Since the modules are prefabricated, there is less need for on-site rework, reducing overall project costs. - Improved safety

Off-site construction reduces the risk of accidents that are commonly associated with on-site construction activities. This is because workers are exposed to fewer hazards when constructing modules in a controlled environment.

Why Choose TechSolutions for Modular Fabrication?

TechSolutions is your trustworthy partner for modularization, we are a leading provider of modularization services, offering integrated solutions for steel structure and pipe modules, from engineering design to pre-commissioning, to ensure that your project is completed efficiently and to the highest standards. Our team of experts has extensive experience in modularization and is committed to delivering exceptional results. We work closely with our clients to understand their specific requirements and provide customized solutions to meet their needs. Some of the reasons why you should choose TechSolutions include:

- Comprehensive services

TechSolutions offers a comprehensive range of modularization services, including engineering design, fabrication, coating, pre-assembly, assembly, and pre-commissioning, logistics. This means that clients can rely on TechSolutions to handle all aspects of the modularization process. We pre-design modules with a “plug-and-play” system ensure the maximum amount of site hours are allocated as efficiently as possible. - Experienced team

TechSolutions has an experienced team of engineers, designers, and technicians who are highly skilled in modularization. They use the latest technologies and equipment to ensure that the modular components are of the highest quality.

Our experienced modularization team will consider all factors in developing the most efficient precast concrete, modularization, pre-assembly, pre-commissioning strategies. - Customized innovative solutions

TechSolutions understands that each project is unique, and therefore offers customized solutions to meet the specific requirements of each client. This means that clients can be assured that their modularization needs will be met.

1) Logistics

We find cost-effective module transportation and installation solutions through considering the balance between optimal module size, the amount of man-hours removed from site, and the cost of transportation.

2) Pre-cast and/or Pre-assembly

We design tailor-made pre-cast and/or pre-assembly, pre-commissioning strategies help minimize on-site man-hours and maximize to cost savings, improves productivity, schedule, and cost certainty. All these strategies can be applied for a wide set of scenarios, including foundations, steel structure modules, pipe modules and mechanical equipment, such as stacker reclaimer, shiploader, car dumper, etc. - Quality assurance

TechSolutions has strict quality control measures in place to ensure that the finished product meets the highest standards of quality. This means that clients can be assured of the quality of the modular components that they receive. - Customer support

TechSolutions offers excellent customer support throughout the entire modularization process. They work closely with clients to ensure that their needs are met and that the project is completed on time and within budget.

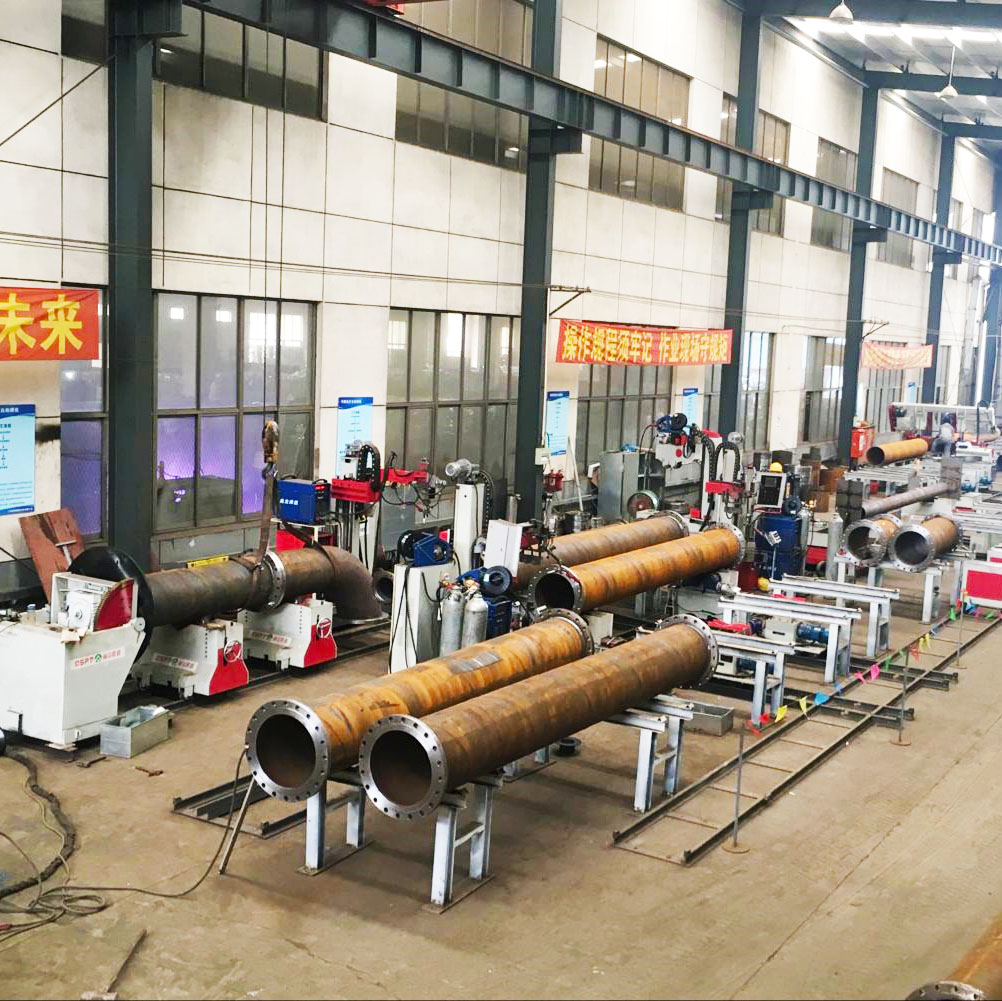

TechSolutions Modular Fabrication Base Facilities

Our modular fabrication base, with over 500,000 square meters, accommodates fabrication of modules weighing more than 7,000 metric tons, specifically designed for efficient fabrication of bulk material handling equipment, port machine, conveyor modules, steel structure modules and pipe rack modules, workflow starts at the back of the modularization fabrication base and moves toward quayside. Items move with the direction of the work, reducing transportation requirements. The facilities at TechSolutions modularization fabrication base include:

- Steel Cutting Workshop

- Structure Welding Workshop

- Blasting & Painting Workshop

- Piping & Outfitting Workshop

- Warehouse

- Assembly workshop

- Pre-assembly Yard

- 8000T Skidway

- 12000T Skidway

- Maintenance & Repair

- #1 Quayside

- #2 Quayside

- Utilities

- Offices

Applications of TechSolutions Modular Fabrication

TechSolutions provides fabrication and modular construction services to Clients in diverse industries, including:

- Mining facilities

- Port and terminal facilities

- Power generation facilities

- Industrial plants such as steel plant, aluminum refinery / smelting plant, etc.

- Oil and gas facilities (Offshore, Deepwater, Subsea and Onshore, Refineries, LNG, Chemicals)

- Bridges and infrastructure

- Commercial and residential buildings

Some typical examples are:

| Mining & Metals | Power |

|---|---|

|

|

| Ports & Terminals | Oil & Gas |

|---|---|

|

|

How can we help you?

Modular fabrication is a modern solution that offers numerous benefits over traditional construction methods. With its cost savings, improved quality control, flexibility, speed of construction, and safety benefits, it is no surprise that modularization fabrication is becoming increasingly popular across various industries.

TechSolutions is a leading provider of integrated solutions for modularization of steel structure modules and pipe modules. Our services include engineering design, fabrication, coating, pre-assembly, assembly, and pre-commissioning. If you’re interested in learning more about our services, please feel free to contact us at service@techsolutions.com.cn or call us at +86 21 6890 6101.

Alternatively, you can contact our sales team using contact form.

FAQs

- What types of facilities can be constructed using modularization fabrication?

Modularization can be used to construct a wide variety of industrial facilities, including oil and gas processing plants, power plants, chemical plants, and more. - How long does it take to complete a modularization fabrication project?

The time required to complete a modularization project will depend on the size and complexity of the facility being constructed. However, modular fabrication can significantly reduce project completion times compared to traditional fabrication methods. - What is difference between modularization fabrication and traditional fabrication?

Modularization offers several advantages over traditional fabrication methods. Traditional fabrication methods involve building components on-site, which can lead to delays and quality control issues. In contrast, modularization fabrication involves building components in a controlled factory environment, where quality control is easier to manage. Modular fabrication also allows for customization and flexibility, as modules can be designed to fit specific project requirements. Traditional fabrication methods may be better suited for smaller projects or those with limited space for transportation and assembly. - What is the future of modularization fabrication?

Modularization fabrication is expected to continue to grow in popularity as the construction industry seeks more efficient and cost-effective solutions. The use of advanced technology, such as Building Information Modeling (BIM) and 3D printing, is also expected to increase the use of modularization fabrication in construction. At TechSolutions, we are committed to staying at the forefront of modularization fabrication technology and providing our clients with the best possible solutions. - What is pre-commissioning?

Pre-commissioning is the process of testing and verifying the functionality of individual modules before they are integrated into the larger facility. - What is quality control in modularization fabrication?

Quality control is a critical aspect of modularization fabrication, and at TechSolutions, we take it very seriously. We have implemented strict quality control measures throughout our fabrication process to ensure that our modules meet the highest standards. - How does modularization fabrication improve safety?

Modularization fabrication reduces the need for on-site welding, cutting, and grinding, which can be hazardous activities. This can significantly reduce the risk of on-site accidents and injuries. - What is safety measures in modularization fabrication?

Safety is a top priority at TechSolutions, and we have implemented stringent safety measures to ensure that our employees and clients are safe at all times.

Technical Data

ROLE

Contractor, PMC, Advisor, etc.

CLIENT INDUSTRIES

Mining & Metals, Power, Oil & Gas, Ports & Terminals, etc.

PROJECT TYPE

EPC, EPC+F, EPCF, EP+S, etc.

SERVED AREA

Worldwide

Note: Above data can be adapted and may vary according to client’s requirement.